|

Assemblage Analysis

The intent of this file is to introduce the concept of assemblage analysis as

it applies to the characterization of an environment. Assemblage

analysis allows the analyst to see groups of particles as a single unit. The

analysis then becomes the recognition of four are five groups of particles

and the discovery of an unusual member or an outlier not belonging to any of

those groups. This simplifies and accelerates the analysis

while increasing the sensitivity to particles that may have special

significance in that environment.

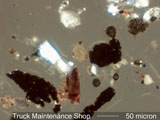

Vehicle Repair Shop Assemblage Key

Vehicle repair includes removal of road dusts, rust, distorted metal, old

paint, etc. The grinding of these surfaces releases abrasives, the matrix

holding the abrasive to the tool (resin, copper, etc), magnetite spheres

from sparks, metal shards with interference films, paint fragments, etc.

Drilling of metal produces metal turnings, the shape of which indicates bit

speed, sharpness, and workrate. Welding and cutting metal leave their own

distinctive particles. Debris from sanding patch materials and paint and

coating spheres round out the assemblage.

|