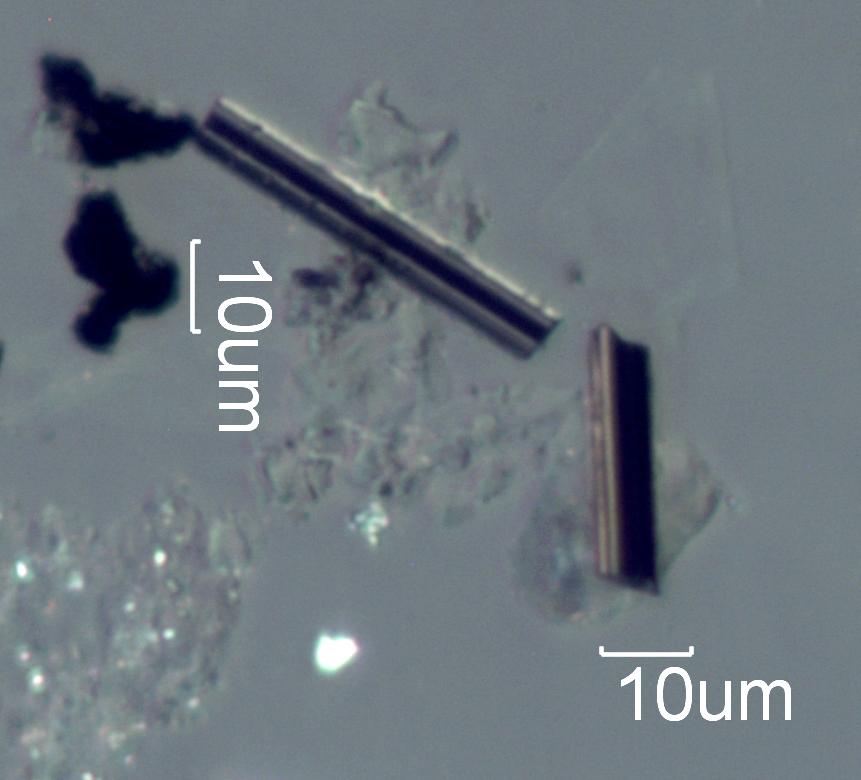

Transmitted Oblique Off Crossed Circular Polarized light and Reflected Darkfield

Illumination

Definition/Function:

Carbon fiber is a fiber produced by thermally processing a plastic or pitch-based

fiber until nearly all of the hydrogen has been removed from the

molecular structure and the carbon atoms have all bonded to other carbon atoms to

form a graphene structure. The size, orientation, and percent of

carbon involved in these graphene units determines the physical and optical

properties of the resulting carbon fiber.

Carbon fiber may be added to plastics to reduce their electrostatic properties and

prevent the development of static-electric charge. Its primary

use is in the design of high strength, light weight, composite materials. These

carbon fiber/resin composite materials are used in sporting goods

such tennis rackets, golf clubs, skis, backpack frames, bicycle frames, etc. They

are used in the bodies of automobiles, airplanes, high pressure

vessels, boat bodies, anywhere high strength and light weight may be desirable.

Carbon fiber/resin composites have been used for their unique optical

properties to make decorator objects or panels.

Significance in the Environment:

Carbon fiber is used as the stiffening, conductive, and strength fiber in a wide variety

of resin/fiber composite materials from skis to airplane

bodies. Its presence in an environment may indicate proximity to a facility that is

involved in the fabrication, refurbishment, or maintenance of

some product that includes a carbon fiber/resin component or a woven carbon fiber

conductive cloth. It may also be present as the result of

mechanical damage to a carbon fiber/resin composite material in the environment sampled.

Characteristic Features:

Carbon fibers are opaque, black, and moderately reflective, about 24% in air and a bit

less, about 18%, in a tapelift preparation. The tension on

the fiber and shrinkage during processing result in surface striations parallel to the

length of the fiber that often act as a diffraction grating

when the incidence of the reflecting beam is perpendicular to the fiber and at the

proper angle. Carbon fibers generally have a diameter between 4

and 8 micrometers. Some may be as much as 12 micrometers. Pitch precursor carbon fiber

tends to be much more variable in diameter with some of the

fibers being much larger in cross-section. A polished cross-section of a carbon

fiber/resin composite examined with reflected and/or transmitted

polarized light revels a great deal about the mechanical properties of the fibers, the

fiber resin bond, and residual stresses in the finished

composite.

Associated Particles:

Carbon fiber associated with damage to a carbon fiber/resin composite will be associated

with fragments of the resin.

References: