Charred Wood and Tire Wear

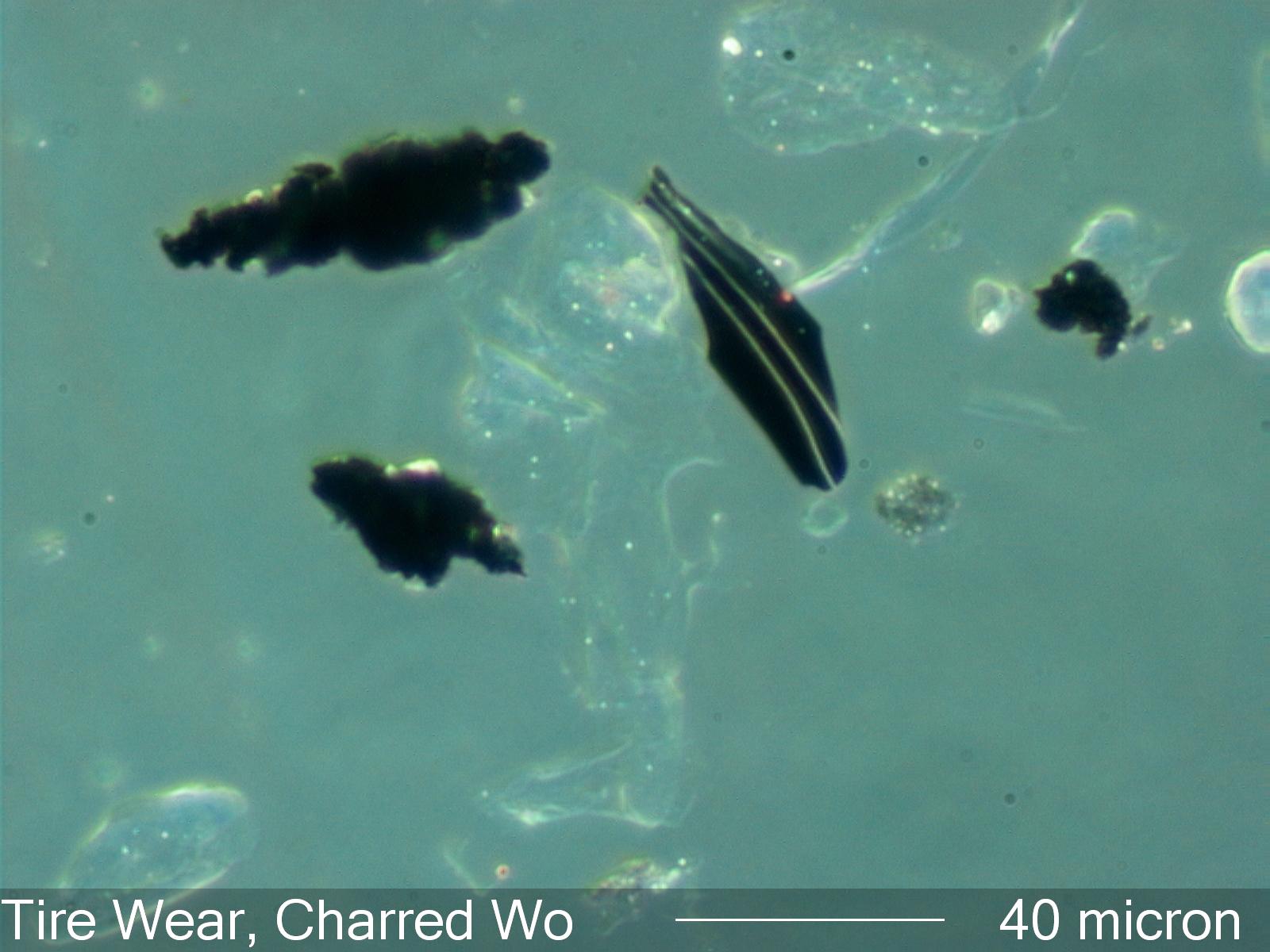

There are three tire wear particles and one charred wood fragment in this image. The charred wood fragment is near the center of the field of view and has sharp, regular boundaries. The tire wear particles have much more complex boundaries and tend toward tapered cylinders, though the smaller fragments, such as the smallest tire wear particle to the right of the charred wood, are more globular in appearance.

Transmitted Circular Polarized Light and Reflected Darkfield Illumination

Definition/Function:

Tire wear particles are a carbonblack pigmented mixture of natural and synthetic elastomers (rubber) with various mineral and fiber fillers and reenforcement. They typically contain from 30% to 45% by weight elastomer. The balance of the weight in the particle is pigment and filler material. Calcite and quartz are two common fillers but wood sawdust, glass, clay, talc, feldspar and other minerals may also be used. Tire wear particles are generated by abrasion as a result of the friction caused by the relative motion between a rubber surface (tire, drivebelt, or conveyer belt) and a non-rubber surface (road, floor, or drive wheel). The shape and size of the particle is determined by the relative properties of the rubber surface, the non-rubber surface, and the force exterted between the two. Truck tires contain more natural rubber by design and that results in longer tapered cylinders than is the case with automoble tires under the same conditions. Very long tapered cylinders are created by the tires of vehicles used in warehouse environments. This is due to the relative smooth surface, which creates larger uniform microenvironments on the contact surface, and the higher rubber content in the tires needed to get traction on the smooth floor.

Drivebelt wear is very similar to tire wear but the associated particle assemblage is different (see below).

Significance in the Environment:

The amount of tire wear particles in an environmental sample indicates the relative proximity to vehicular traffic and the relative ease of transport from that source to the sample site. For indoor environments the population is normalized against skin flakes, paper fiber, and clothing fiber. For outdoor environments it can be normalized against the plant and fungal background. High concentrations of tire wear generally indicate a high exposure to vehicle emission.

"Tire wear" particles may also indicate wear of black rubber drive belts in the HVAC system or in other locations where a black rubber surface rubs against a non-rubber surface.

Characteristic Features:

Tire wear particles are characterized by their very rough texture and "fractile" outline. The particles tend to be tapered cylinders with the aspect ratio determined by the texture of the non-rubber surface and the amount and type of elastomer in the tire or rubber belt. Thin edges of the particle are transparent, depending on the concentration and distribution of the black pigment. Filler minerals typically protude from the edges of the particle at a few locations along the edge and can be seen between crossed polarizing filters. Off crossed circular polarized light (slight rotation of one of the polarizing filters) can be very useful in order to see the black particle outline as well as the birefringent filler particles. Darkfield reflected light is also very useful to characterize the surface texture of the particle.

Tire wear particles can be destinguished from large combustion particles by the presence of small highlight reflectivity on the tire wear particles caused by the refractive indix difference between the rubber and the mounting medium and the larger granularity of the rubber particle surface.

Tire wear particles can be destinguished from large cenospheres (carbonized liquid fuel, typically from Bunker C fueled boilers) by the higher reflectivity of the cenosphere surface due to the graphine structure of the carbon in the cenosphere.

Tire wear particles can be destinguished from charred wood and plant material by the cell morphology and higher reflectivity of the charred plant material.

There are three tire wear particles and one charred wood fragment in this image. The charred wood fragment is near the center of the field of view and has sharp, regular boundaries. The tire wear particles have much more complex boundaries and tend toward tapered cylinders, though the smaller fragments, such as the smallest tire wear particle to the right of the charred wood, are more globular in appearance. Reflected darkfield illumination brings out another difference in charred wood and tire wear, their reflectivity. Charred wood tends to be a strong reflector of light due to its smooth surface. the bright highlights shown by the charred wood fiber along some of the cell boundaries illustrate this property. Tire wear particles are very poor reflectors due to their rough surface, near matching refractive index of the transparent elastomeric matrix and the mounting medium, and the high absorption coefficient of the carbon black suspended in the elastomer. The transparent properties of the elastomer are best seen in this image as the graying at the edges due to light scatter by the elastomer. The light is scattered by the surface of the elastomer before it can be absorbed by the carbon black contained beneath the surface. Subsequent photographs of this field with different types of illumination will illustrate other differences that aid in the differentiation of these black particles.

Associated Particles:

Tire wear is typically associated with a road wear mineral content greater than that of the tire wear component of the sample. If tire wear exceeds the road wear mineral content then a parking garage environment may be indicated. If that is not the case then another black rubber wear source must be present. Pollens, spores, plant parts, and other outdoor particles are generally associated with the tire wear. If they are less evident then mechanical transport of tire wear from outside is indicated and other mechanically transported particles; such as moss fragments, etc.; should be present.

Drive belt wear particles are typically associated with the HVAC blower in office and school environments. If the drive belt for the blower is the source then other typical HVAC agglomerates will also be seen in the sample. If they are not seen then another source of black rubber wear particles should be found.

References:

There are three tire wear particles and one charred wood fragment in this image. The charred wood fragment is near the center of the field of view and has sharp, regular boundaries. The tire wear particles have much more complex boundaries and tend toward tapered cylinders, though the smaller fragments, such as the smallest tire wear particle to the right of the charred wood, are more globular in appearance. Reflected darkfield illumination brings out another difference in charred wood and tire wear, their reflectivity. Charred wood tends to be a strong reflector of light due to its smooth surface. the bright highlights shown by the charred wood fiber along some of the cell boundaries illustrate this property. Tire wear particles are very poor reflectors due to their rough surface, near matching refractive index of the transparent elastomeric matrix and the mounting medium, and the high absorption coefficient of the carbon black suspended in the elastomer. The transparent properties of the elastomer are best seen in this image as the graying at the edges due to light scatter by the elastomer. The light is scattered by the surface of the elastomer before it can be absorbed by the carbon black contained beneath the surface. Subsequent photographs of this field with different types of illumination will illustrate other differences that aid in the differentiation of these black particles.

Definition/Function:

Tire wear particles are a carbonblack pigmented mixture of natural and synthetic elastomers (rubber) with various mineral and fiber fillers and reenforcement. They typically contain from 30% to 45% by weight elastomer. The balance of the weight in the particle is pigment and filler material. Calcite and quartz are two common fillers but wood sawdust, glass, clay, talc, feldspar and other minerals may also be used. Tire wear particles are generated by abrasion as a result of the friction caused by the relative motion between a rubber surface (tire, drivebelt, or conveyer belt) and a non-rubber surface (road, floor, or drive wheel). The shape and size of the particle is determined by the relative properties of the rubber surface, the non-rubber surface, and the force exterted between the two. Truck tires contain more natural rubber by design and that results in longer tapered cylinders than is the case with automoble tires under the same conditions. Very long tapered cylinders are created by the tires of vehicles used in warehouse environments. This is due to the relative smooth surface, which creates larger uniform microenvironments on the contact surface, and the higher rubber content in the tires needed to get traction on the smooth floor.

Drivebelt wear is very similar to tire wear but the associated particle assemblage is different (see below).

Significance in the Environment:

The amount of tire wear particles in an environmental sample indicates the relative proximity to vehicular traffic and the relative ease of transport from that source to the sample site. For indoor environments the population is normalized against skin flakes, paper fiber, and clothing fiber. For outdoor environments it can be normalized against the plant and fungal background. High concentrations of tire wear generally indicate a high exposure to vehicle emission.

"Tire wear" particles may also indicate wear of black rubber drive belts in the HVAC system or in other locations where a black rubber surface rubs against a non-rubber surface.

Characteristic Features:

Tire wear particles are characterized by their very rough texture and "fractile" outline. The particles tend to be tapered cylinders with the aspect ratio determined by the texture of the non-rubber surface and the amount and type of elastomer in the tire or rubber belt. Thin edges of the particle are transparent, depending on the concentration and distribution of the black pigment. Filler minerals typically protude from the edges of the particle at a few locations along the edge and can be seen between crossed polarizing filters. Off crossed circular polarized light (slight rotation of one of the polarizing filters) can be very useful in order to see the black particle outline as well as the birefringent filler particles. Darkfield reflected light is also very useful to characterize the surface texture of the particle.

Tire wear particles can be destinguished from large combustion particles by the presence of small highlight reflectivity on the tire wear particles caused by the refractive indix difference between the rubber and the mounting medium and the larger granularity of the rubber particle surface.

Tire wear particles can be destinguished from large cenospheres (carbonized liquid fuel, typically from Bunker C fueled boilers) by the higher reflectivity of the cenosphere surface due to the graphine structure of the carbon in the cenosphere.

Tire wear particles can be destinguished from charred wood and plant material by the cell morphology and higher reflectivity of the charred plant material.

There are three tire wear particles and one charred wood fragment in this image. The charred wood fragment is near the center of the field of view and has sharp, regular boundaries. The tire wear particles have much more complex boundaries and tend toward tapered cylinders, though the smaller fragments, such as the smallest tire wear particle to the right of the charred wood, are more globular in appearance. Reflected darkfield illumination brings out another difference in charred wood and tire wear, their reflectivity. Charred wood tends to be a strong reflector of light due to its smooth surface. the bright highlights shown by the charred wood fiber along some of the cell boundaries illustrate this property. Tire wear particles are very poor reflectors due to their rough surface, near matching refractive index of the transparent elastomeric matrix and the mounting medium, and the high absorption coefficient of the carbon black suspended in the elastomer. The transparent properties of the elastomer are best seen in this image as the graying at the edges due to light scatter by the elastomer. The light is scattered by the surface of the elastomer before it can be absorbed by the carbon black contained beneath the surface. Subsequent photographs of this field with different types of illumination will illustrate other differences that aid in the differentiation of these black particles.

Associated Particles:

Tire wear is typically associated with a road wear mineral content greater than that of the tire wear component of the sample. If tire wear exceeds the road wear mineral content then a parking garage environment may be indicated. If that is not the case then another black rubber wear source must be present. Pollens, spores, plant parts, and other outdoor particles are generally associated with the tire wear. If they are less evident then mechanical transport of tire wear from outside is indicated and other mechanically transported particles; such as moss fragments, etc.; should be present.

Drive belt wear particles are typically associated with the HVAC blower in office and school environments. If the drive belt for the blower is the source then other typical HVAC agglomerates will also be seen in the sample. If they are not seen then another source of black rubber wear particles should be found.

References:

There are three tire wear particles and one charred wood fragment in this image. The charred wood fragment is near the center of the field of view and has sharp, regular boundaries. The tire wear particles have much more complex boundaries and tend toward tapered cylinders, though the smaller fragments, such as the smallest tire wear particle to the right of the charred wood, are more globular in appearance. Reflected darkfield illumination brings out another difference in charred wood and tire wear, their reflectivity. Charred wood tends to be a strong reflector of light due to its smooth surface. the bright highlights shown by the charred wood fiber along some of the cell boundaries illustrate this property. Tire wear particles are very poor reflectors due to their rough surface, near matching refractive index of the transparent elastomeric matrix and the mounting medium, and the high absorption coefficient of the carbon black suspended in the elastomer. The transparent properties of the elastomer are best seen in this image as the graying at the edges due to light scatter by the elastomer. The light is scattered by the surface of the elastomer before it can be absorbed by the carbon black contained beneath the surface. Subsequent photographs of this field with different types of illumination will illustrate other differences that aid in the differentiation of these black particles.