Garnet

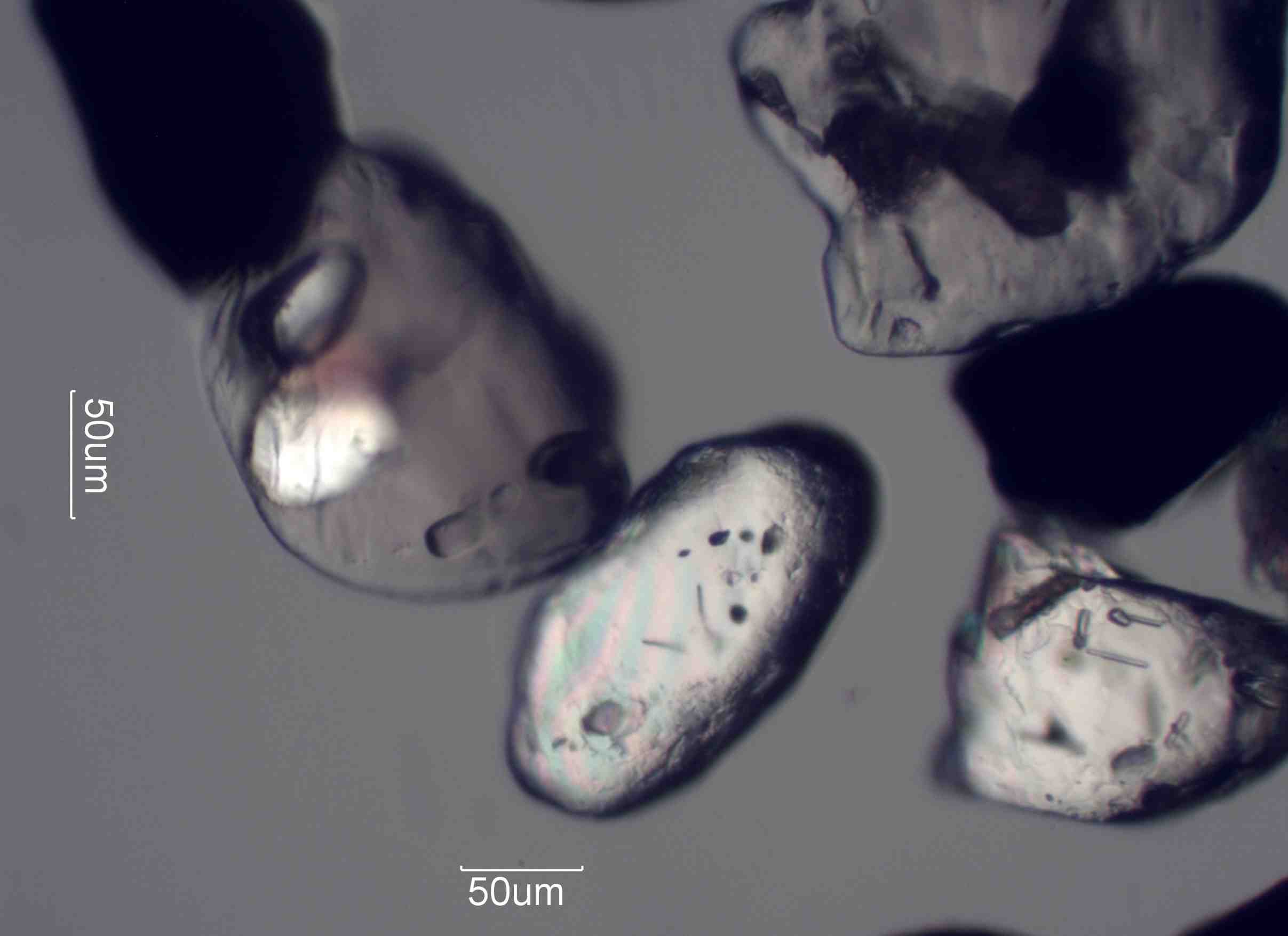

The grain on the upper right and left center are garnets from Stonefield Beach State Park in Oregon. The grains in the center and lower right are a zircons and the black grains are magnetite.

Transmitted Oblique Off Crossed Circular Polarized Light

Hydrogrossular 1.675 to 1.734; Colorless under the microscope;

Pyrope 1.714; Colorless to pink or purple under the microscope

Grossular 1.734; Generally Colorless under the microscope;

Spessartine 1.800; Colorless to pink or brown under the microscope

Almandine 1.830; Colorless to pinkish-red under the microscope;

Uvarovite 1.865; Green under the microscope

Andradite 1.887; Colorless to brown under the microscope

Their density generally exceeds 3.5 grams per cubic centimeter.

Brady, George S. and Henry R. Clauser, MATERIALS HANDBOOK, McGraw-Hill, ISBN 0-07-007069-5, pp.334-336, 1979.

Gillson, Joseph L. (editor-in-chief), INDUSTRIAL MINERALS AND ROCKS, American Institute of Mining, Metallurgial, and Petroleum Engineers, pp. 9-14, 1960.

Definition/Function:

The Garnet group includes Pyrope, Almandine, Spessartine, Grossular, Andradite, Uvarovite, and Hydrogrossular. The first four have the general chemical composition X3Al2Si3O12 where X is Mg for Pyrope, Fe for Almandine, Mn for Spessartine, and Ca for Grossular. The chemical composition for Andradite is Ca3(Fe,Ti)2Si3O12. The chemical composition for Uvarovite is Ca3Cr2Si3O12. The chemical composition for Hydrogrossular is Ca3Al2Si2O8(SiO8)(1-m)(OH)4m. Almandine is the most common and refers to any garnet dominated by the end member almandine formulation. One example of almandine provided by Deer, Howe, and Zussman is Alm66Gro25Py5Sp4. The garnets form two basic solid solutions. The first is the "pyralspite" group, which consists of solid solutions of the first three listed above: Pyrope, Almandine, and Spessartine. The second is the "ugrandite" group, which consists of the other four: Grossular, Andradite, Uvarovite, and Hydrogrossular.Significance in the Environment:

Rounded, smooth garnet grains indicate ocean beaches where the current has concentrated heavy minerals. Rounded grains with a frosted surface indicates wind blown processing. Rounded garnet grains are from natural sources rather than from the use of garnet as an abrasive. Sharp, angular grains are typical of mountain streams or rivers closer to the source of the minerals. Angular grains may be from sandpaper or grinding wheels being used for abrasive shaping or smoothing of wood, plastics, or metals. the most common abrasive garnets are almandite or andradite dominated garnets.Characteristic Features:

Garnets belongs to the cubic crystal system and are isotropic. The refractive indices for the different types of garnets are as follows:Hydrogrossular 1.675 to 1.734; Colorless under the microscope;

Pyrope 1.714; Colorless to pink or purple under the microscope

Grossular 1.734; Generally Colorless under the microscope;

Spessartine 1.800; Colorless to pink or brown under the microscope

Almandine 1.830; Colorless to pinkish-red under the microscope;

Uvarovite 1.865; Green under the microscope

Andradite 1.887; Colorless to brown under the microscope

Their density generally exceeds 3.5 grams per cubic centimeter.

Associated Particles:

Garnets are a common mineral in heavy mineral beach sands (black sands) and strandline deposits. Magnetite, hornblende, tourmaline, zircon, ilmenite, monazite, chromite, etc. may be common associated particles. Garnets from sandpaper or disks may be associated with resin and with the abraded material being shaped or smoothed.References:

Deer, W. A., R. A. Howie, and J. Zussman, AN INTRODCUTION TO THE ROCK-FORMING MINERALS, ISBN 0-582-30094-0, pp. 31-46, 1992.Brady, George S. and Henry R. Clauser, MATERIALS HANDBOOK, McGraw-Hill, ISBN 0-07-007069-5, pp.334-336, 1979.

Gillson, Joseph L. (editor-in-chief), INDUSTRIAL MINERALS AND ROCKS, American Institute of Mining, Metallurgial, and Petroleum Engineers, pp. 9-14, 1960.