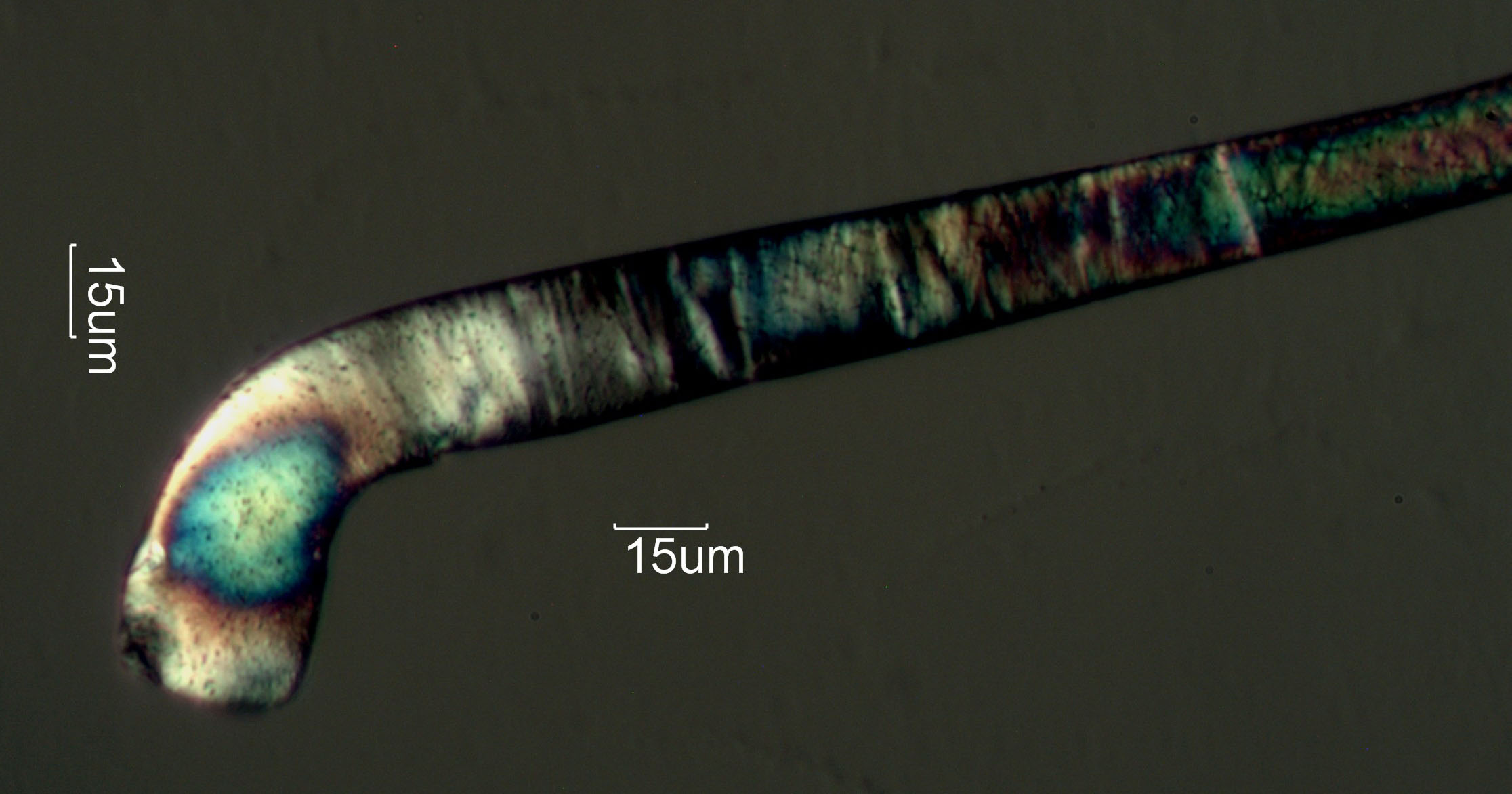

Nylon Fiber, Melt Termination

This is a sample nylon with a termination created by melting. It shows considerable misalignment of the polymer strands as indicated by the reduced interference color at the end of the fiber. Melting has also resulted in a thickening of the fiber at the end.

Transmitted Off-Crossed Circular Polarized Light

DuPont Company Techinical Bulletin X-156: IDENTIFICATION OF FIBERS IN TEXTILE MATERIALS, December 1961.

http://en.wikipedia.org/wiki/Nylon

Definition/Function:

Nylon fiber is a polyamide fiber. It is formed by the careful combination of a diamine and a dicarboxylic acid or by a ring- opening polymerization. It is formed into a fiber by extruding the heated polymer through a spinneret. This results in the The fiber taking the cross-section of the spinneret. Nylon fiber can be round or any other desirable extruded shape.Significance in the Environment:

This is a common clothing fiber.Characteristic Features:

Nylon fiber has a refractive index along its length of about 1.57 to 1.59 and perpendicular to its length of about 1.51 to 1.53. It has a birefringence of about 0.06 and a positive sign of elongation. It tends to exhibit a smooth, regular surface along its length depending on its cross-section of the fiber. Extreme shapes, such as the trilobate Type 1775, can result in an irregular appearance along the length as the fiber twists or bends.Associated Particles:

References:

Gorski, Azriel and Walter C. McCrone, "Birefringence of fibers", THE MICROSCOPE, vol. 46, no. 1, pp. 3-16DuPont Company Techinical Bulletin X-156: IDENTIFICATION OF FIBERS IN TEXTILE MATERIALS, December 1961.

http://en.wikipedia.org/wiki/Nylon