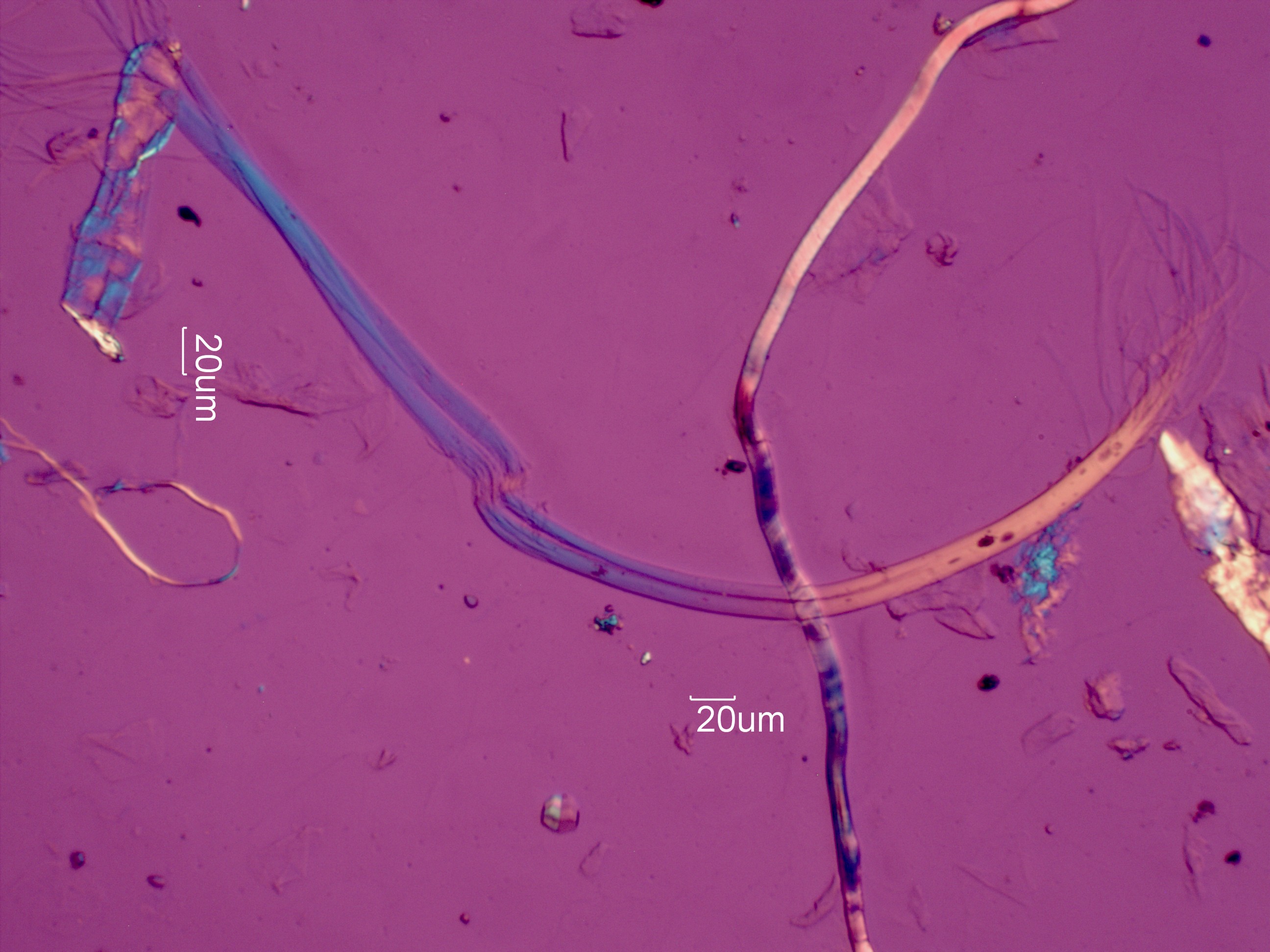

Acrylic Fiber, Mechanical Damage

This is a sample of mechanically damaged acrylic fiber. The stress has resulted in the formation of more strongly aligned fibrils of the polymer within the fiber. This is expressed as broomed terminations and fragmenting of the fiber along its length.

Transmitted Crossed Linear Polarized Light With the Red Plate Compensator

http://en.wikipedia.org/wiki/Acrylic_fiber

Definition/Function:

Acrylic fiber is derived from petrolium products. It is formed by drawing the polymer in solution through a spinneret into a bath where it solidifies from the outside in. This results in less than a circular cross-section because the outside polymerizes first and is drawn more rapidly though the bath than the interior of the fiber that is still liquid. The draw-rate and process affects the fiber diameter, birefringence, and the cross-sectional shape, from nearly round, to bean shaped, to dog-bone, to slightly crinulate. Acrylic fiber was commertially producted starting in about 1944.Significance in the Environment:

This is a common clothing fiber.Characteristic Features:

Acrylic fiber has a refractive index along its length of about 1.50 to 1.53 and perpendicular to its length of about 1.50 to 1.53. It has a birefringence of about 0.002 to 0.012 and a negative sign of elongation. It may exhibit slight irregular striations along its length due to the crinulate cross-section of the fiber, one depression along its length in the case of the dog-bone cross-section, or appear to vary in diameter due to a bean shaped cross-section.Associated Particles:

References:

DuPont Company Techinical Bulletin X-156: IDENTIFICATION OF FIBERS IN TEXTILE MATERIALS, December 1961.http://en.wikipedia.org/wiki/Acrylic_fiber