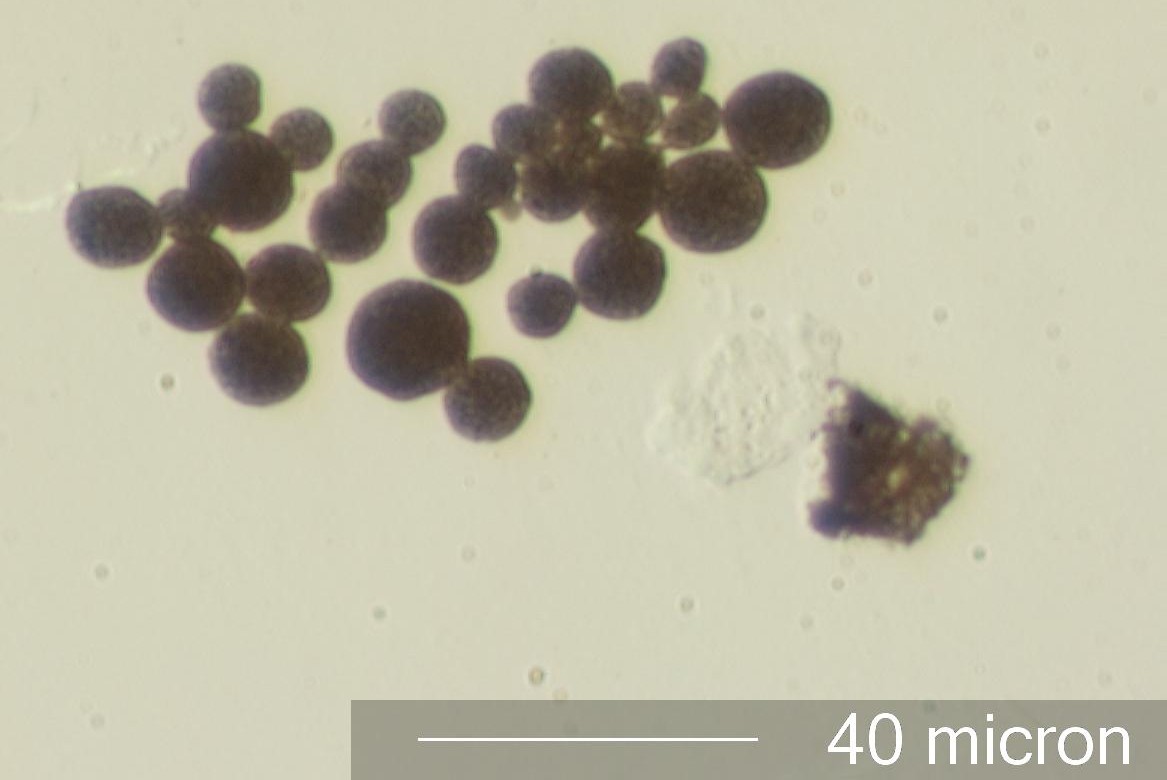

Transmitted Off Crossed Circular Polarized Light

Definition/Function:

There are many different types of toner particles but they all share the fact that

they are composed of a pigment or dye in a

transparent thermoplastic matrix. The individual toner particles may be spherical,

globular, or irrigular in shape in there

unused condition. Once they have been bonded to paper they tend to be irregular in

shape and often exhibit plastic

deformation as a result of the forces that removed them from the paper to which they

had been bonded. Sometimes a small

fragment of paper will be attached to the toner particle that was worn from the

surface of the printed paper.

Significance in the Environment:

The presence of these particles in the environment indicate the presence of a printer or

copy machine. If unused toner

particles are found in the environment it suggests that the machine is not functioning

properly. There may be particle

emission or ozone emission issues associated with the machine. These may result in a

cosmetic problem (discoloring clothing),

irritation of mucus membranes, or other problems, depending on the nature a quantity of

materials being generated by the

printer or copier. Ozone is a known toxin but the hazards of the other materials that

are generated by printers and copiers

are unknown. Particles generated by printers and copiers tend to be predominantly from

the paper being used rather than

the toner or inks used in them. Some wear plastic and wear metal particles are created

from the moving parts of the machines

but most of the particle come from the paper being feed through the friction drive of

the machine. That is one of the many

reasons why particle counts around copy machines and printers tend to vary from time to

time with the same machine, the

same level of activity, and even with "similar" paper. Particle counters cannot

differentiate between toner, ink, particles

of wear, or paper sizing particles. Literature such as that published by Linda Morawska

(see below) should be interpreted cautiously,

as she, herself, suggests.

Characteristic Features:

Toner particle may be often be recognized their transparent matrix and the distribution

of pigment particles or dye. Some

toners contain very small, well dispersed pigment and may appear completely colored.

They will exhibit very little if any

reflectivity and no edge birefringence. Cenospheres exhibit much higher reflectivity and

show a complex surface texture not

seen in toner particles. Weld spheres exhibit edge birefringence between crossed

polarizers, are smooth, and show surface

reflectivity. Paint spheres tend to be much larger and generally include a greater

variety of materials, including pigments,

opacifiers, and bulking agents. The matrix for the toner particles is typically a

polyethylene, a polystyrene, or a polyester. The

polystyrene and some of the polyester matrices are soluble in acetone. In a tapelift

processed using acetone the matrix

will dissolve resulting in free pigment particles and thin films of matrix material

together under the tape at the location

of the original particle.

Associated Particles:

Toner particles are typical of office environments. They are typically found with

mechanically abraded paper, paper sizing,

toner coated paper fibers, and then with the other types of particles common in offices.

References:

http://en.wikipedia.org/wiki/Toner

Morawska, Lidia, Congrong He, and len Taplin, "Particle Emission Characteristics of

Office Printers", International

Laboratory for Air Quality and Health (Queensland University of Technology); Queensland

Department of Public Works, SF Gate,

2007-07-10, pp. 1–7.