Lubrication Film Wear, Track Wear

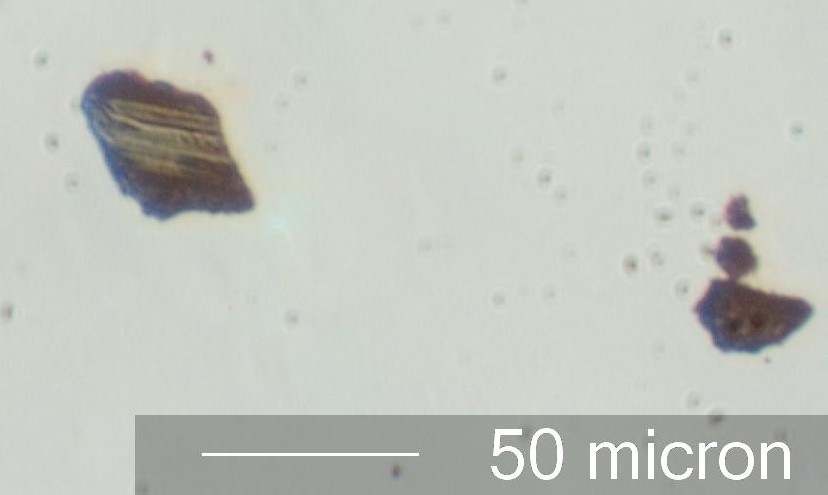

These particles are a little unusual because they are not

the typical elongated, tapered cylinder, but they are track wear just

the same. These particles broke away from the track surface as fragments of the

lubricating film. The linear striations of the roller are evident on the

particle at left. These particles auto-welded to the roller but disengaged and

became airborne before a full rotation of the roller.

Transmitted Off Crossed Circular Polarized Light and Reflected Darkfield Illumination

Definition/Function:

These particles are an example of lubrication film wear typical of roller-track

environments. These include

file cabinet drawers, desk drawers, and even overhead cranes. They are formed by the

slight slippage that occurs during motion and

the hydrocarbon film that develops on the metal runner over time. These particles are

typically black, with an organic matrix and

significant numbers of very small metal wear particles.

Significance in the Environment:

Characteristic Features:

Track wear particles tend to have low reflectivity because the polymer matrix is

transparent. The pattern of the reflection indicates

a smooth surface by virtue of its conformance to the gross morphology of the particle.

Associated Particles:

References: