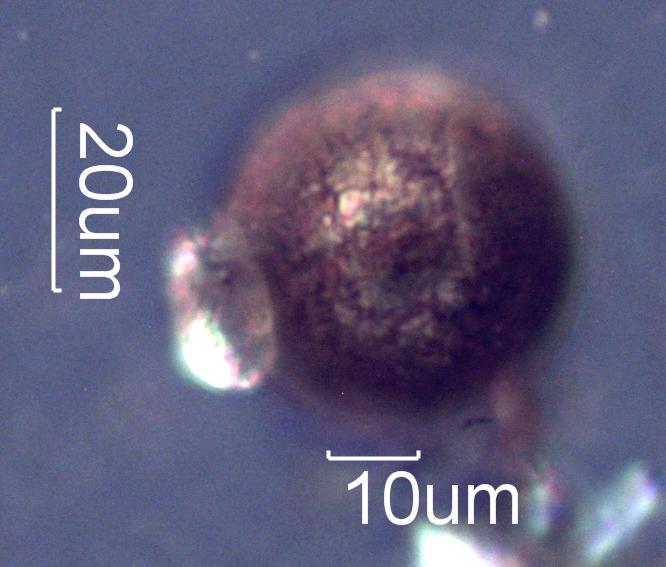

Corroded Copper Arc Sphere

This is a copper arc sphere generated by arcing and then corroded by the oil over time. The etched appearance and "lacing" of the particle shows its corrosion.

Definition/Function:

Copper arcing spheres are generated when an arc is discharged in the transformer under the cover of oil. It is the result of molten copper being formed by the arc and ejected into the oil by the rapid thermal expansion of the metal under the molten metal. The size of the arc particle is an indication of the strength of the arc.

Corrosion of copper in a transformer fill with mineral oil can be due to a number of different chemical compounds. The most frequent corrosive agents are low molecular weight organic acids. Some peroxides are also very corrosive to copper but the product of the reaction tends to be a copper salt of an organic acid due to the catalytic reaction between the copper and the peroxide.

Significance in the Environment:

There has been some energetic arcing going on in this transformer as indicated by the large size of the arc sphere. The oil in this transformer is corrosive to copper.