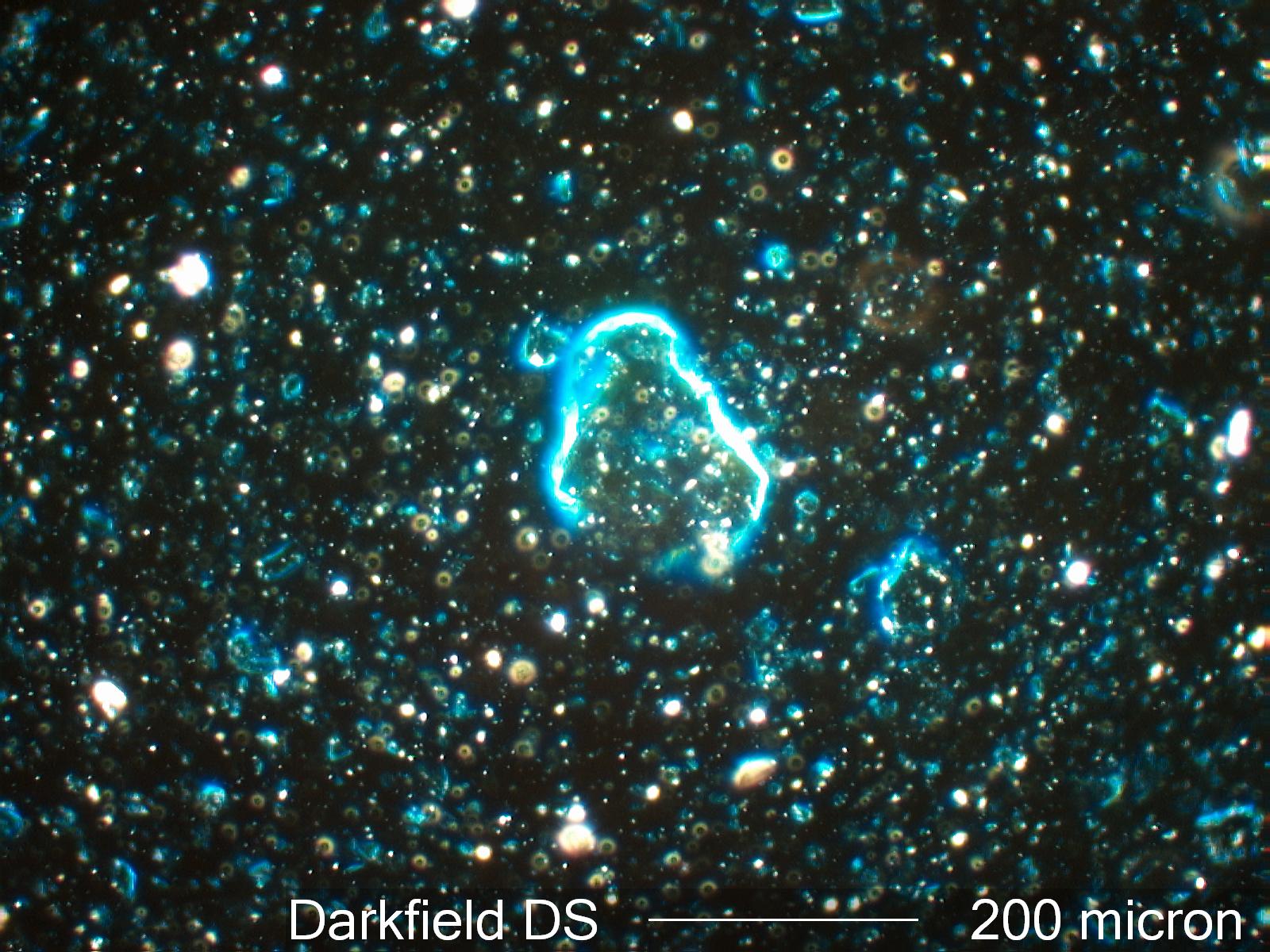

Darkfield Dispersion Staining

These are the colors seen when using darkfield illumination with the 1.66 optical glass standard in Cargille Melt Mount 1.662 refractive index liquid. The wavelength at which this glass and this liquid match is 670 nanometers. The difference in dispersion is 0.012.

Definition/Function:

Dispersion Staining is an optical staining technique created by differences in the dispersion of the refractive indices for a particle and the liquid in which it is mounted. Darkfield dispersion staining is one of the five methods of dispersion staining. It results in a single color, similar to the objective central stop dispersion staining method, to assess the wavelength at which the particle and liquid match. It produces brilliant colors and is very effective for particles larger than about 10 micrometers with most standard illumination sources.Conditional Requirments:

This approach works best with a mounting medium that has a steep dispersion curve. Most liquids with refractive indices above 1.60 meet that requirement. There are "high dispersion" liquids sold commercially designed specifically for dispersion staining. These sets normally start at a refractive index of 1.500 and go up to about 1.700. The particles of interest are mounted in one of these liquids that matches the refractive index of the particles at some visible wavelength. High dispersion liquids can also be made by mixing cinnamic aldehyde (R.I. about 1.62) with triethyl phosphate (R.I. 1.406), or methylene Iodide (R.I. 1.737). A less expensive set of high dispersion liquids can be made with cinnamon oil, also called cassia oil (R.I. about 1.60) and clove oil (R.I. about 1.53) or caster oil (R.I. about 1.48). These oils can generally be purchased at any local drugstore. When liquids are mixed it is good to test them against standard glasses or minerals on a regular basis. The commercial refractive index liquids are designed for long term stability.

The particles must be mounted under a coverslip to optimize the effects and minimize in interference cause by any optical anomaly in an unmounted specimen.