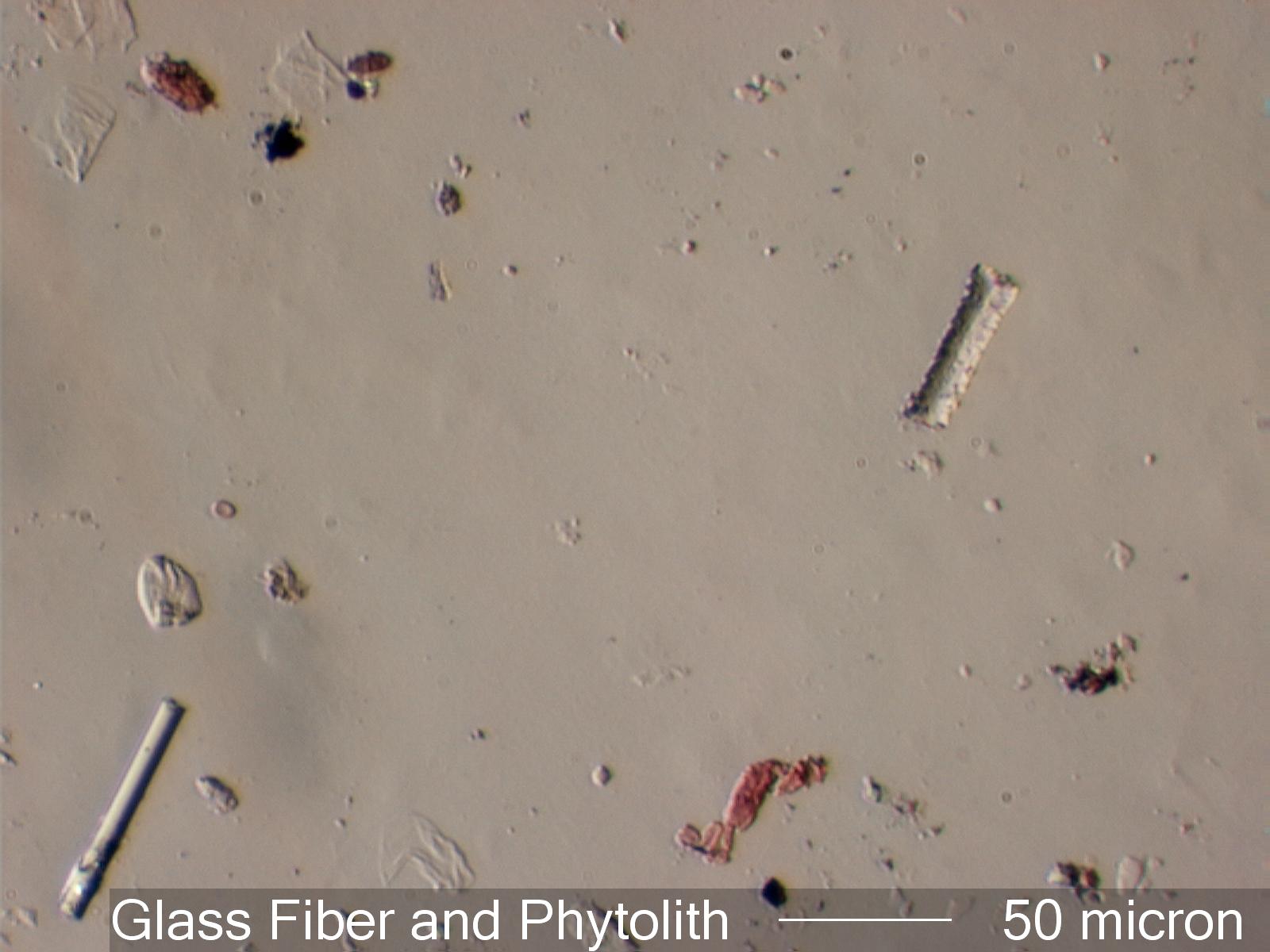

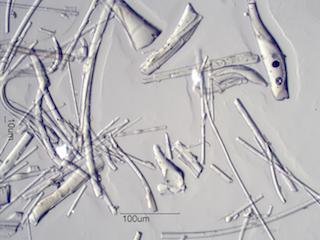

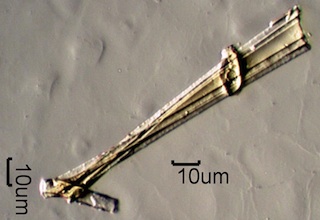

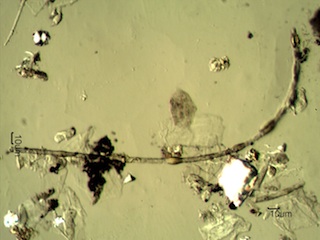

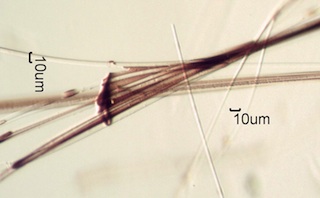

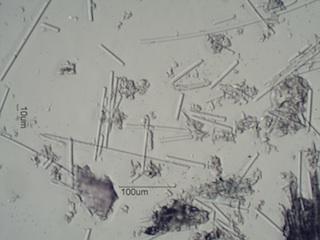

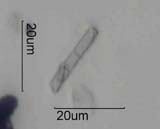

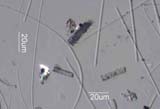

Glass fiber, as used here, is any isotropic fiber with a cross-section consistent with formation by surface tension, sharp or abrupt terminations, and with visible inclusions limited to elongated bubbles. Glass fiber is a major cause of Building Related Illness. The paper below is from the Indoor Air 2011 Conference in Austin, Texas, paper 81. Health Complaints and Environmental Glass Fiber Acoustic ceiling tile that contains glass fiber can be divided into two basic groups by their gross appearance. The body of the tile is either compact and gray or loose and yellow. The gray tile exhibits the greatest variability in composition, from nearly 90% glass fiber to about 10% glass fiber. The other materials in the body of the tile may include perolite, paper fiber, clay, calcite, glass shot, glass blebs, and asbestos. Glass fiber from acoustic ceiling tile is identified by the other materials still attached to it. Clear epoxy binder, sodium silicate, or similar clear binder containing small particles of calcite filler and binding the glass fiber to any of the other possible materials used to make these tiles identifies the glass as coming from acoustic ceiling tile.

The yellow bodied acoustic ceiling tile that contains glass fiber is composed of

glass fiber and

yellow phenolic resin. The amount of resin and the amount of mineral filler used

in the resin varies

from one grade to another and from one manufacturer to another. Glass fiber from

yellow bodied

acoustic ceiling tile can often be distinguished from other yellow phenolic

bound glass fiber.

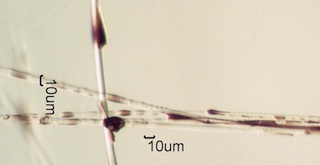

Yellow phenolic bound glass fiber from sound board in the HVAC system is

generally covered with

small impacted particles of natural minerals, soot, pollens and other airborne

particles. Yellow

phenolic bound glass fibers from blanket insulation typically contain much less

mineral filler in

the resin. Yellow phenolic bound glass fiber from cubicle divider panels tends

to contain much

more yellow resin than the yellow bodied acoustic ceiling tile. See the "Glass

Fiber" section of

the gallery for examples of all these materials.

The yellow bodied acoustic ceiling tile that contains glass fiber is composed of

glass fiber and

yellow phenolic resin. The amount of resin and the amount of mineral filler used

in the resin varies

from one grade to another and from one manufacturer to another. Glass fiber from

yellow bodied

acoustic ceiling tile can often be distinguished from other yellow phenolic

bound glass fiber.

Yellow phenolic bound glass fiber from sound board in the HVAC system is

generally covered with

small impacted particles of natural minerals, soot, pollens and other airborne

particles. Yellow

phenolic bound glass fibers from blanket insulation typically contain much less

mineral filler in

the resin. Yellow phenolic bound glass fiber from cubicle divider panels tends

to contain much

more yellow resin than the yellow bodied acoustic ceiling tile. See the "Glass

Fiber" section of

the gallery for examples of all these materials.

A common structure for a cubicle divider consists of a metal frame supporting

a resin stiffened glass

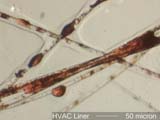

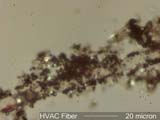

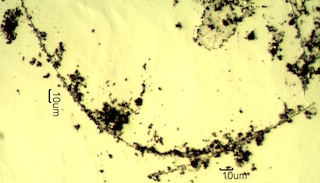

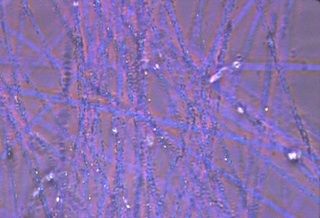

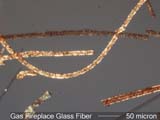

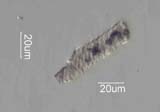

The HVAC system is a common source of glass fiber in indoor office and school

environments. These

glass fibers are generally coated with particles impacted onto their surfaces

that mark them as having

been exposed to a moving air stream. These impacted particles typically have

diameters smaller than

that of the fiber on which they rest. The color of the resin associated with

glass fiber from the

HVAC system varies. It may be yellow, orange, red, green, gray, or black. The

same "soundboard" may

have more than one color of resin on it. One common combination is a yellow

resin used for the bulk

of the glass fiber mat with a coating of black, mineral-filled resin on the

outer surface of the panel.

The resin used for the soundboard panels is generally heavily filled with clay

or silica.

The HVAC system is a common source of glass fiber in indoor office and school

environments. These

glass fibers are generally coated with particles impacted onto their surfaces

that mark them as having

been exposed to a moving air stream. These impacted particles typically have

diameters smaller than

that of the fiber on which they rest. The color of the resin associated with

glass fiber from the

HVAC system varies. It may be yellow, orange, red, green, gray, or black. The

same "soundboard" may

have more than one color of resin on it. One common combination is a yellow

resin used for the bulk

of the glass fiber mat with a coating of black, mineral-filled resin on the

outer surface of the panel.

The resin used for the soundboard panels is generally heavily filled with clay

or silica.

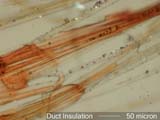

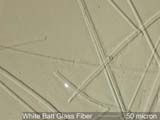

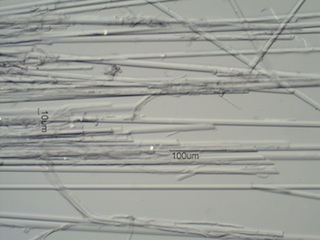

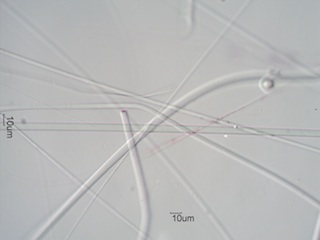

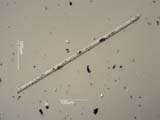

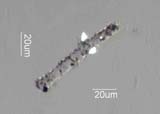

Thermal blanket insulation is made from glass wool with a small amount of resin

to bind the fibers

together in order to maintain loft. The resin is typically yellow, pink, or

colorless (white). The fibers

tend to be clean other than the presence of the resin when found in

environmental samples though

is some instances, where they have been exposed to air flow, they can become

coated with particles and

look similar to ventilation system glass fibers.

Thermal blanket insulation is made from glass wool with a small amount of resin

to bind the fibers

together in order to maintain loft. The resin is typically yellow, pink, or

colorless (white). The fibers

tend to be clean other than the presence of the resin when found in

environmental samples though

is some instances, where they have been exposed to air flow, they can become

coated with particles and

look similar to ventilation system glass fibers.

Exposed to Building Fires

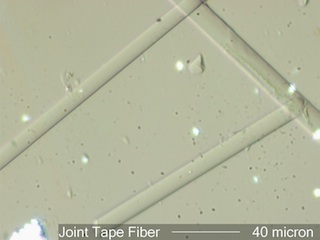

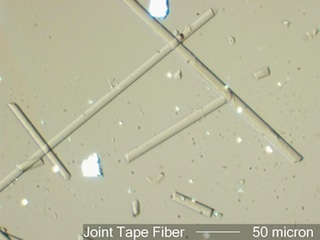

Glass fiber from the tape used to smooth the joint between two panels of drywall is often found following construction but it is rarely at levels that could result in health complaints by itself. It often contributes to the overall glass fiber loading in buildings as as result of construction.

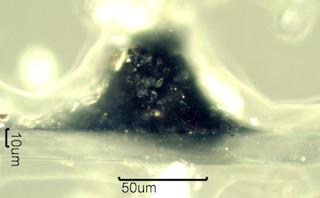

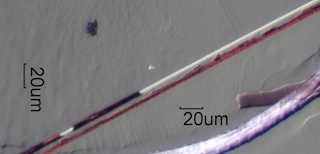

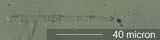

Recycled Glass Fiber as Blown-in Insulation Recycled glass fiber is often used as blown-in "green" insulation. It is "green" only in the environmental sense. The glass fiber is thermally treated to clean it which results in the old binder being charred.

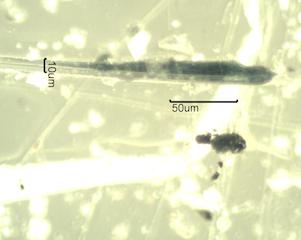

Cutting glass fiber composite materials creates a significant amount of free, short glass fiber. Individuals doing this work seldom complain about the effects of exposure but the glass fiber dust they may carry into other environments may result in healt complaints by others now exposed. One example is glass fiber from removing fiberglass casts in a clinic. This dust can result in complaints by others working in the clinic if the dust is not adiquitely controlled.

Identifying Glass FiberBird Feather Barbules

Plastic Fiber

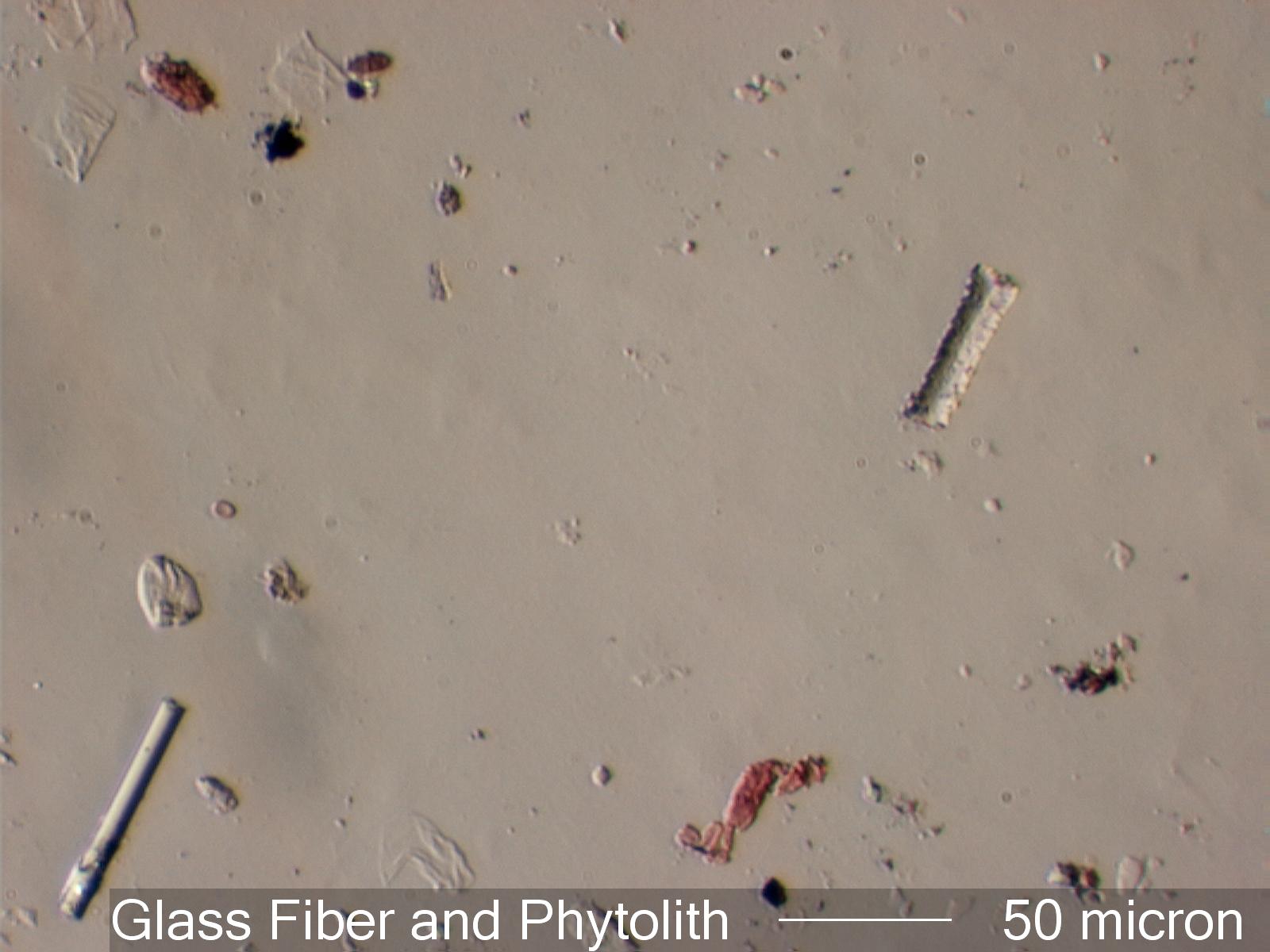

Phytoliths

Diatoms, etc.

Sponge Spicules

Insect Hair (Setae)

|