|

Topics in Light Microscopy

Anomalous Birefringence

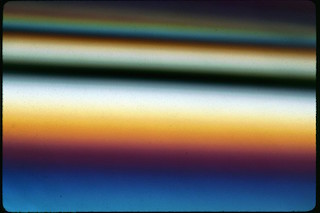

Anomalous birefringence is simply the result of a material's birefringence

changing in a significant way as a function of the wavelenght of

light. It produces anomalous interference colors in the material being

examined between crossed polarizing filters.

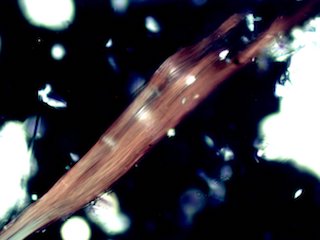

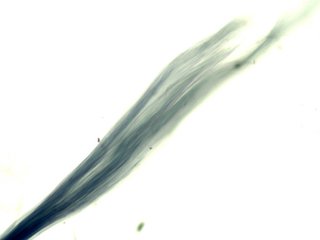

Crocidolite, Higher Birefringence in Red Light (longer Wavelengths)

Very thin fibers appear red between crossed polarizing filters. Thicker

fibers appear blue because of the strong blue color of the mineral.

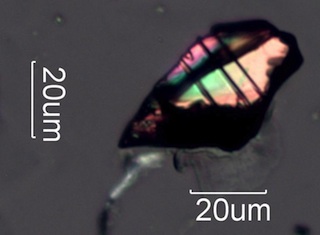

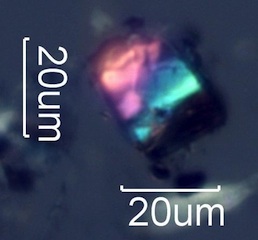

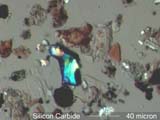

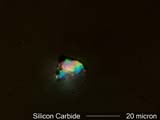

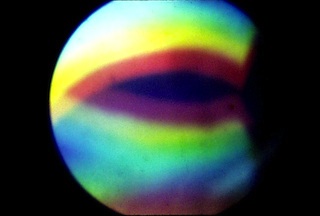

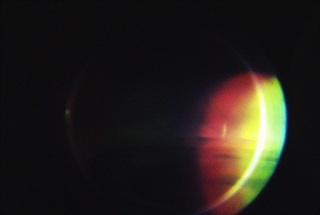

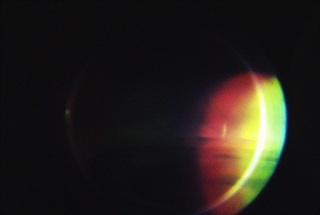

Silicon Carbide, Higher Birefringence in Blue Light (Shorter Wavelenghts)

Blue wavelengths cycle more rapidly than red wavelengths. Yellow interference

color begins for thinner particles and first order red appears

purple because blue is increasing well before red significantly decreases.

This effect changes the color sequence through the whole range of

microscopic silicon carbide particles.

Apparent Birefringence

Polarized light can be depolarized by light scatter or by specular reflection at

an interface that is not aligned with the

orientation of the polarized beam. Birefringence can be induced by stress in

materials that are otherwise isotropic.

Ordered distributions of regular shaped isotropic particles or fibers with a

different refractive indix than an isotropic

matrix can induce an apparent birefringence. Click on the photographs below for

more information.

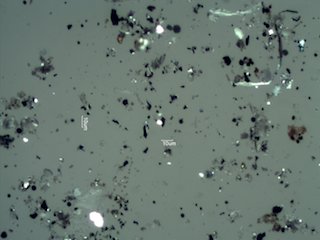

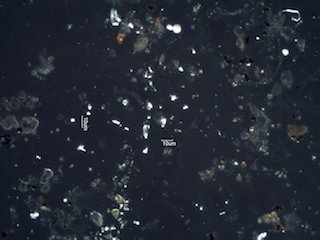

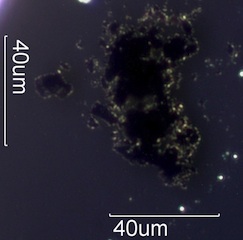

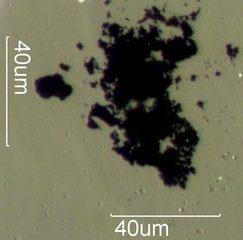

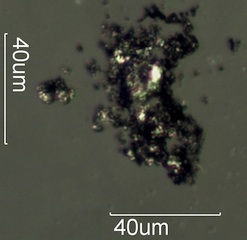

Edge Effect Birefringence

Polarized light is depolarized at the interface between a conductive particle

and a non-conductive mounting medium. This light halo effect with

transmitted crossed polarized light indicates an opaque particle is a wear

metal particle or at least is conductive. Graphite is sufficiently

conductive

to produce this effect. Pencil debris can be distinguished from combustion

residue by this effect.

Graphite

Magnetite Spheres

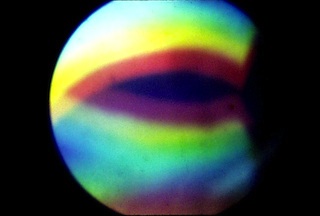

Stress Birefringence

When a material is placed under stress the distribution of the electrons in the

material is changed. The amount of change is different for each

material and is a characteristic of the material. The photoelastic constant of

the matrial is a measure of the electron displacement (strain) as a

function of the load (stress) applied as long as the deformation is elastic,

springs back when the load is removed. If the YOung's Modulus of the

matrial is exceeded then some of the deformation becomes permenant. In some

materials the applied load can be "frozen" in place, as in the case of

high stress glass sheet. Polarized light can make the displacement visible. Both

plastic deformation and elastic deformation result in an

anisotropic distribution of electrons in the material that becomes visible as

interference colors when the object is viewed between crossed linear or

crossed circular polarizing filters. Click on the photographs below for more

information.

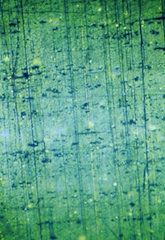

Birefringence from Plastic Deformation in Human Skin Cells

Birefringence from Plastic Deformation in Human Skin Cells

Birefringence from Plastic Deformation in Dog Skin Cells

Birefringence from Plastic Deformation in Dog Skin Cells

Stress Birefringence in Safety Glass

Stress Birefringence in Safety Glass

Resolution vs Visibility Through the Microscope

The resolution of objects viewed through the light microscope is a calculated

value based on configuration of the microscope.

Visibility is a function of contrast. To take advantage of resolution there must

be sufficient contrast to see the subject

but objects far below the resolution limit of a specific microscope

configuration can be made visible with sufficient

contrast. This is the same phenomena that allows us to see the stars in the

night sky, all of which are far below the

resolution limit of our eyes. A few examples through the microscope are provided

below showing methods of improving the

resolution and/or visibility of objects viewed through the "standard" light

microscope. Click on the photographs below for

more information.

Resolution and Ocular Magnification

The resolution of the microscope is determined by the objective and the

condenser. The ocular must provide sufficient

magnification for the observer to see what is being resolved. The images below

provide a simple example.

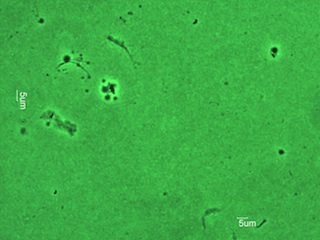

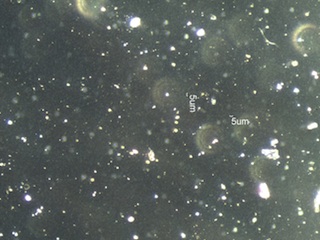

Brightfield vs Darkfield Illumination

Brightfield vs Oblique Illumination

TN.jpg)

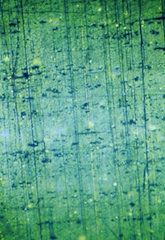

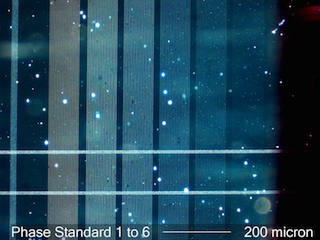

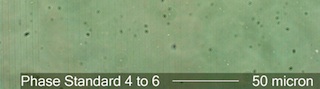

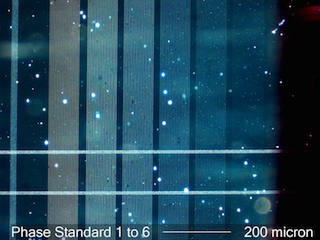

Phase Contrast vs Visibility Through the Microscope

Phase contrast microscopy makes "phase" objects more visible. Every object is a

"phase" object strictly speaking but some objects are

primarily phase objects, being nearly invisible using standard brightfield

illumination. Phase constrast does not always improve

visibility. Small objects with significantly different refractive indices than

the medium in which they are mounted will be visible using

darkfield illumination even when they are invisible using phase contrast. The

"Phase Contrast Test Slide" is a good example, as shown

below.

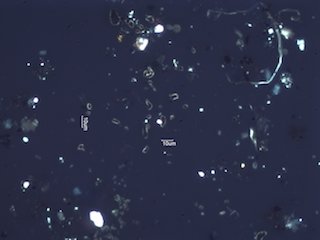

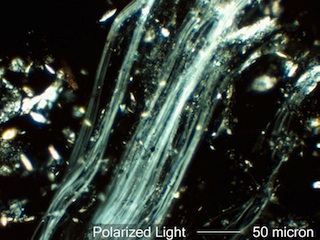

Polarized Light vs Visibility Through the Microscope

Objects with more than one refractive index can be made self-luminous by using

crossed polarized light. This can create sufficient contrast to see the

object.

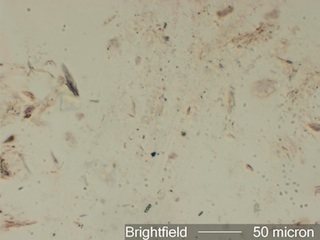

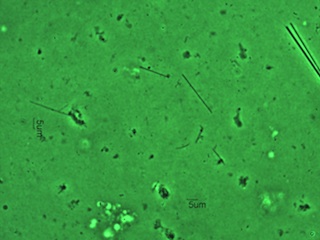

Asbestos Fibers and Visibility Through the Light Microscope

Much has been made of the need for transmission electron microscopy (TEM)

"because the light microscope can't see

asbestos fibers thinner than 0.25 micrometers". This quote is in error on many

counts, but is a common

misconception. First, it is not the microscope that "sees", but rather the human

eye establishes the detection limit.

If the light source is not "on" the resolution limit for the microscope has not

changed but the eye won't see anything.

Second, the ability to "see" (detect) an object is not dependent on resolution.

This point has been made for the general

case above but will be made again here in the specific case of asbestos fibers.

Third, after over thirty years of

diligent searching there has been no evidence that asbestos fibers shorter than

five micrometers cause any health effect

more detrimental than nuisance dust. Fresh crystalline silica is more

detrimental in this respect. That challenges the

"need" for an instrument that can "see" particles that are not apparently

detrimental as a replacement for light

microscopy. We will continue monitoring with the TEM because it is required in

many governement and industrial

regulations, but it is not a "superior" method in the case of hazardous asbestos

detection or identification at sites

of asbestos removal projects.

|